Acid reducing cleaner YY-RCA series

The dyeing process of disperse dyes is divided into two stages: (1) dyeing the fibers with dyes and (2) reduction cleaning.

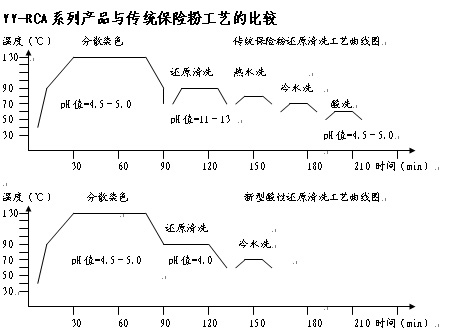

The conventional reduction cleaning process is generally sodium hydrosulfite (2~3g/L) plus soda ash (2g/L), treated at 80 ℃ for 20 min. However, due to the strong pungent smell of sodium hydrosulfite, serious environmental pollution, unsafe transportation and use, the fabric is easy to change color and yellow after reduction cleaning, and the fabric strength is seriously damaged. in addition, since that dye of the disperse dye is carried out unde the acidic condition with the pH value of 4 to 5, a large amount of alkali agent is added in the reduction cleaning process to meet the reduction condition of the sodium hydrosulfite, and an acid agent is adde for neutralization after the reduction cleaning, so that the process conditions are complicated, the process flow is long, and the process cost is high. Therefore, according to the market demand, it is necessary to develop a kind of acid reduction detergent for disperse dyes, which is energy-saving, environment-friendly, short process flow, strong reduction cleaning ability and low comprehensive cost. The company and Xi'an Textile University jointly developed disperse dyes acid reduction cleaning agent YY-RCA has a strong reduction cleaning ability, and the fabric does not change color after reduction cleaning, product performance is stable, energy-saving environmental protection, free formaldehyde. After the dyeing is finished, the reduction cleaning can be directly carried out under the acidic condition without draining and adding an alkali agent, the process flow is shortened, the dosage is only 1/3 - 1/2 of the dosage of the sodium hydrosulfite, and the comprehensive cost of production and processing is greatly reduced. The dyeing fastness of polyester fabric dyed with disperse dyes by this product is higher than that by conventional sodium hydrosulfite process.

This product has been included in the second batch of science and technology projects in 2009 - 2010

Advantages of YY-RCA Series

1. Compared with the traditional sodium hydrosulfite reduction cleaning, it has higher color fastness.

2. Compared with the traditional process, the process of drainage, water injection, heating and neutralization is omitted, and the acid reduction cleaning can shorten the process time by about 30% and save water consumption by 40%.

3. The dosage of sodium hydrosulfite in the conventional sodium hydrosulfite/alkali reduction cleaning process is 2~3g/L, while the dosage of acid reduction cleaning process YY-RCA-1 is up to 2g/L

4. In addition to saving time and water, the use of acid reduction cleaning can reduce energy consumption, reduce sewage discharge, and reduce the COD value.

5. Non-hazardous, very low toxicity, easy to store in warehouse.